A Metal Particle Sensor (MPS) is crucial in various industries for several reasons, primarily related to the detection and monitoring of wear and contamination in machinery and equipment. Here’s why an MPS is so important:

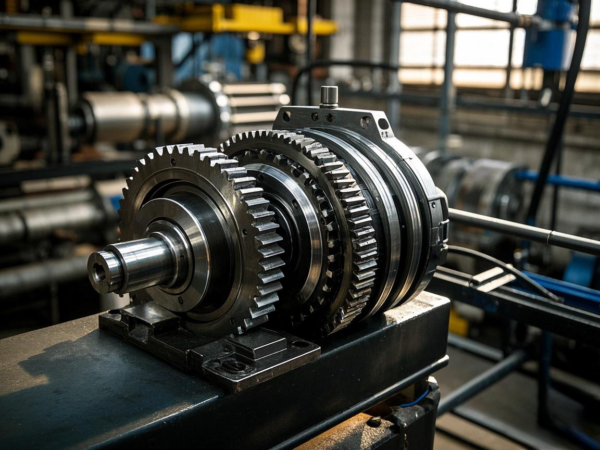

- Early Detection of Wear: MPS devices detect metal particles in lubricating oil, hydraulic fluid, or other machinery fluids. The presence of metal particles can indicate wear and tear of internal components, such as bearings, gears, or other moving parts. Early detection helps in identifying wear before it leads to significant damage or failure.

- Preventative Maintenance: By monitoring the concentration and size of metal particles, MPS allows for predictive maintenance rather than reactive maintenance. This means that maintenance can be scheduled before a failure occurs, minimizing downtime and reducing the risk of catastrophic failures.

- Cost Savings: Preventative maintenance enabled by MPS can save significant costs associated with unscheduled downtime, extensive repairs, and equipment replacement. Early intervention can prevent minor issues from escalating into major problems.

- Improved Safety: In industries such as aviation, automotive, and heavy machinery, the failure of critical components can lead to severe accidents and safety hazards. MPS helps ensure the safety and reliability of these systems by providing early warnings of potential issues.

- Extended Equipment Life: Regular monitoring and maintenance based on MPS data can extend the lifespan of machinery and equipment. By addressing wear and contamination issues promptly, the overall durability and performance of equipment are improved.

- Quality Control: In manufacturing processes, particularly those involving precision machinery, the presence of metal particles can compromise product quality. MPS helps maintain high standards of quality control by ensuring machinery operates smoothly and without contamination.

- Compliance and Standards: Many industries have strict regulations and standards regarding equipment maintenance and operational safety. Using MPS can help companies comply with these standards by providing documented evidence of regular monitoring and maintenance practices.

- Real-Time Monitoring: Advanced MPS systems offer real-time monitoring and data analysis, allowing for immediate action when abnormal wear or contamination levels are detected. This capability is vital for critical applications where any delay in response can lead to significant consequences.

Overall, Metal Particle Sensors play a vital role in maintaining the health, efficiency, and safety of machinery and equipment across various industries. Their ability to provide early warnings and facilitate proactive maintenance makes them indispensable in modern industrial operations.