Description

- High-precision laser and photoelectric transceiver components ensure measurement accuracy

- Suitable for various liquids, real-time monitoring of cleanliness levels 24/7

- Ensures safe operation of hydraulic and lubrication systems, preventing excessive contamination

- Optional online detection of oil moisture saturation level for enhanced diagnostics

- Internal storage of up to 3,000 test records

- Compact, robust, durable, intelligent, and easy to integrate

- Built-in flow estimation function ensures measurement accuracy

- Detects abnormal contamination and wear to safeguard asset operation

- Continuous and interval measurement modes are freely configurable

- Fast response with adjustable accumulation and measurement cycles

- Excellent chemical resistance and high-pressure tolerance

- Dual certification for EMC and explosion protection, ensuring long-term stable operation in harsh environments

- No moving parts or consumables, designed for a 10-year service life

- 5 kV isolated RS485 Modbus communication

Suitable for liquids

Hydraulic oil, lubricating oil, insulating oil, turbine oil, engine oil, aviation kerosene, diesel fuel, ethylene glycol fire-resistant hydraulic fluid, phosphate ester hydraulic fluid, cooking oil, cutting fluids, ultrapure water, pharmaceutical solutions.

Applicable Industries

Aviation, aerospace, defense, oil, chemicals, power generation, energy, metallurgy, steel, transportation, ports, oil filtration, engineering, machinery, hydraulics, automotive, pharmaceuticals, electronics, semiconductors, research, laboratories and so on.

Measurement Principle | Light Extinction Method (Optical Blockage) |

Sensing Element | Semiconductor laser, photodetector |

Detection Range | 1–100 μm (ISO 4402), 4–70 μm(c) (ISO 11171, GB/T 18854) |

Detection Channels (8 channels)

| ISO 4402: 1, 2, 5, 10, 15, 25, 50, 100 μm or |

Sensitivity | ISO 4402: 1 μm |

Calibration Standard | ISO 4402 (ACFTD, GBW(E)120017) |

Built-in Standards | ISO 4406: Grades 0–28 |

Measurement Accuracy

| ±0.5 cleanliness code (depends on flow stability) |

Permissible Flow Rate

| 10–500 mL/min optimal at 25 mL/min) |

Fluid Viscosity

| ≤680 cSt |

Coincidence Error Limit

| 20,000 particles/mL |

Maximum Allowable Oil Pressure

| 0–3 MPa (continuous), up to 5 MPa (transient peak); up to 42 MPa with optional pressure-reducing valve |

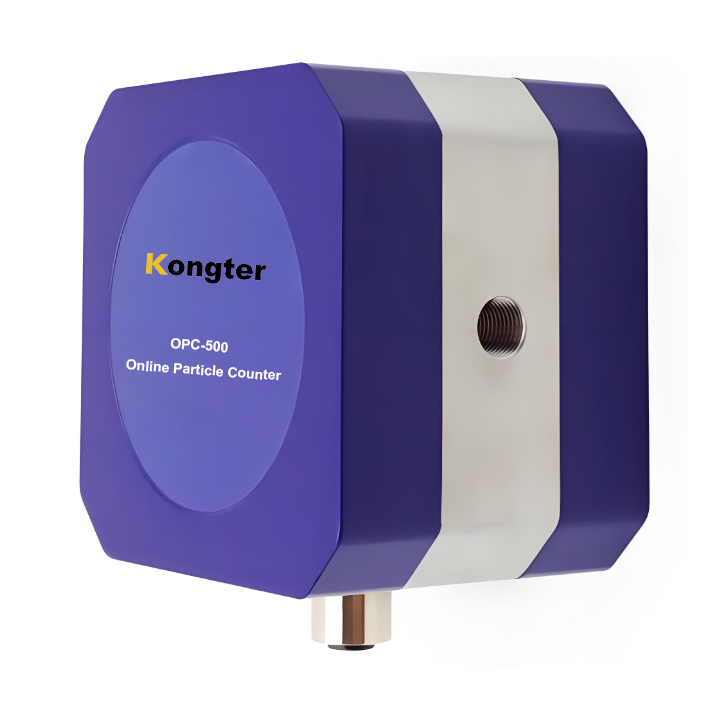

Oil Line Connection Port | M10×1.0 mm internal thread |

Digital Output | RS485 Modbus RTU, 2 kV isolation voltage |

Operating Power Supply | DC 10–28 V, <60 mA @ DC 24 V, Max 2 W |

Applicable Fluids | Lubricating oil, hydraulic oil, kerosene, reagents, water-based fluids, etc.(Phosphate ester fluids available on request) |

Fluid Temperature | -20 °C to 85 °C |

Ambient Temperature | -20 °C to 60 °C |

Storage Temperature | -40 °C to 85 °C |

Housing Material | Stainless steel (explosion-proof version) or anodized aluminum (industrial version), polycarbonate |

Wetted Materials | NBR, FKM, glass, stainless steel, aluminum alloy |

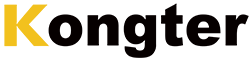

Dimensions | 80 × 80 × 60 mm (L × W × H) |

Weight | <800 g |

Protection Rating (IP Rating) | IP66 |

Connection Cable | 2 m long 5-core cable, M12×1.5-5 pin connector or M12 cable gland |

Electromagnetic Compatibility (EMC) | EN 61000, EN 61326-1, EN 61326-2, EN 61326-4 |

Vibration Resistance | 2 g |

Explosion Protection Rating (Optional) | Ex ib IIC T6 Gb |

Trace Moisture (Optional) | 0–5000 ppm (calibrated per oil sample), accuracy ±10% |

Water Activity (Optional) | 0–1 aw (equivalent to 0–100% RH moisture saturation), accuracy ±3% |

Oil Temperature (Optional) | -40 °C to 85 °C, accuracy ±0.5 °C |

The OPC-500 online particle counter uses the light obscuration (light-scattering) principle and is calibrated using standard reference materials such as MTD (ISO Medium Test Dust, ISO 11171) or ACFTD (Air Cleaner Fine Test Dust, ISO 4402).

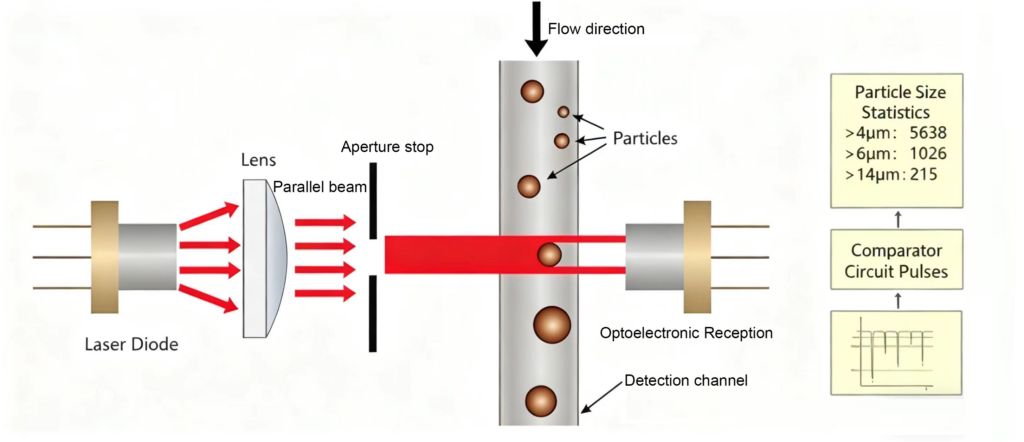

OPC-500 features a high-performance semiconductor laser that, via a collimating lens, directs a parallel beam into the oil detection channel inside the counter. Paired with a high-efficiency PIN photodetector serving as the signal-receiving unit, it enables real-time monitoring of particle count and contamination levels.

When no particles pass through the liquid, the detection circuit outputs a constant voltage. However, as particles move through the detection channel, they block the light beam, causing the photocurrent to weaken. Consequently, the photoelectric signal received by the photodetector also diminishes, triggering the detection circuit to output a pulse signal. Since the detection channel is narrow enough to ensure that particles in the liquid pass through one by one in sequence, each pulse detected corresponds to a single particle passing through the channel. By counting the number of pulses generated, you can accurately determine how many particles have traveled through the detection area.

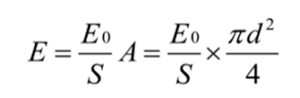

The amplitude of the negative pulse is related to the particle size according to the following equation. This enables counting solid particles in oil and, based on different standards, facilitates real-time online detection and classification of liquid contamination levels.

E —— represents the voltage pulse value, in millivolts, generated as particles pass through the detection area,mV

E0 —— The voltage reference value, in mV, generated by the photoelectric detector when no particles pass through the detection area,mV

A —— Effective receiving area of the photoelectric detector,μm2 ;

S —— The projected area of the particle in the direction of the light beam,μm2 ;

d —— When the particle is spherical, it represents the particle diameter, in μm.

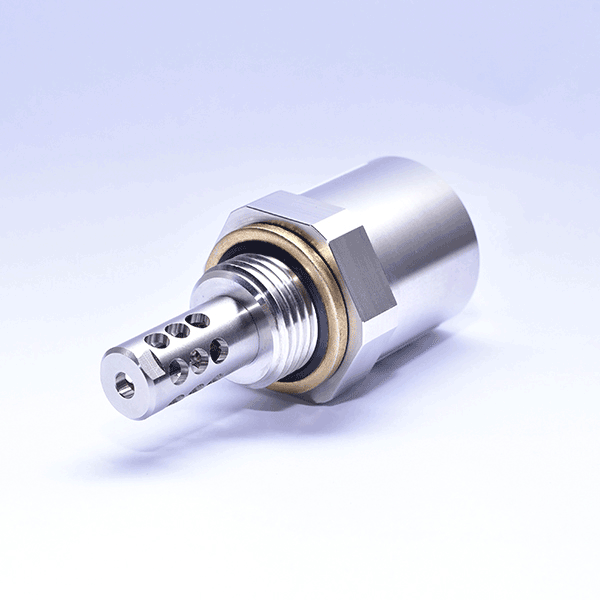

The product also offers optional features for measuring dissolved moisture content (expressed in ppm), water activity (aw, moisture saturation RH%), and temperature. It is available under the model number OPC-500-W.

OPC-500-W measures water activity by integrating high-performance polyimide film capacitors, paired with a PT100 platinum resistance sensor, enabling real-time detection of dissolved moisture in oil. Leveraging its built-in multiple calibration coefficients for water solubility, the device accurately monitors both dissolved moisture levels in parts per million (ppm) and water activity (aw), ensuring at all times that oil moisture remains below the saturation point—and providing you with comprehensive diagnostic insights to safeguard your valuable equipment.

Customers also viewed: