Description

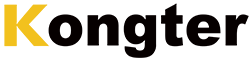

The OMS-300 is equipped with an industry-leading high-precision and high-stability wear debris detection module. This module employs an advanced multi-coil magnetic field disturbance detection principle, combined with a high-performance data sampling and processing unit, to achieve real-time capture and cumulative output of ferromagnetic particles ≥40µm and non-ferromagnetic particles ≥150µm.

The OMS-300 also features built-in internal temperature measurement and oil flow velocity measurement, enabling self-diagnosis of the sensor’s operating environment and judgment of oil circuit flow. This ensures the sensor always operates in an optimal detection state and guarantees the representativeness of the oil sample being monitored.

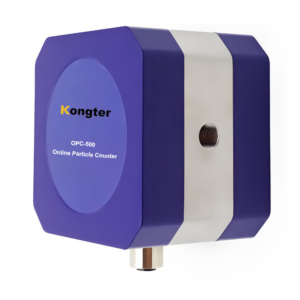

The introduction of the OMS-300 enables real-time monitoring of the wear condition of large industrial equipment. By continuously monitoring the generation of wear debris and the oil’s physicochemical indicators, it can alert users to perform maintenance at the earliest stages of equipment failure. Compared to traditional maintenance schedules, this allows for lower-cost maintenance measures and helps prevent larger, more serious accidents.

- Detection capability for 40µm Ferromagnetic & 150µm Non-ferromagnetic wear debris.

- Wear debris count statistics and material analysis.

- Detection of multiple physicochemical indicators including viscosity, density, and trace moisture.

- Flow velocity estimation to ensure the representativeness of the measurement.

- Early detection of abnormal wear to protect valuable assets.

- Measurement is immune to interference from external metals and magnetic fields.

- Measurement is unaffected by bubbles and moisture in the oil.

- Fast response, with adjustable data accumulation cycles.

- Excellent chemical corrosion resistance and pressure tolerance.

- No moving parts or consumables, designed for a 10-year lifespan.

- 2.5 kV isolated RS485 Modbus communication.

| Ferromagnetic & Non-ferromagnetic Particles, Kinematic Viscosity, Density, Trace Moisture, Water Activity, Temperature, Flow Velocity | |

| Optional: Dielectric Constant, Free Water | |

| Ferromagnetic & Non-ferromagnetic Wear Debris Detection | |

| Detection Capability | Ferromagnetic Particles (Fe) > 40 µm (ESD), Five Bands |

| Non-ferromagnetic Particles (NFe) > 150 µm (ESD), Five Bands | |

| Particle Passage Diameter | Φ 8 mm |

| Detection Rate | > 90% |

| Ferromagnetic Statistics | 40~99µm, 100~199µm, 200~299µm, 300~399µm, ≥ 400µm |

| Non-ferromagnetic Statistics | 150~199µm, 200~299µm, 300~399µm, 400~499µm, ≥ 500µm |

| Statistics Cycle | Startup self-test 30 seconds (first time), counting interval 300~3600 seconds adjustable |

| Particle Count | Max 100 particles/second |

| Oil Property Detection | |

| Viscosity Detection | Range: 1…1000cSt (larger ranges available upon request) |

| Accuracy: 5% or 5cSt, whichever is greater | |

| Resolution: 0.1cSt | |

| Density Detection | Range: 600…1250 kg·m⁻³ |

| Accuracy: 2% or 5 kg·m⁻³, whichever is greater | |

| Resolution: 0.1 kg·m⁻³ | |

| Trace Moisture | Range: 1…5000ppm (calibrated based on oil type) |

| Accuracy: 10% or 10ppm | |

| Resolution: 1ppm | |

| Water Activity | Range: 0…1aw |

| Accuracy: 3% | |

| Resolution: 0.001aw | |

| Temperature | Range: -40…85℃ |

| Accuracy: 0.5℃ | |

| Resolution: 0.1℃ | |

| Dielectric Constant (Optional) | Range: 1…6εr |

| Accuracy: 0.2εr | |

| Resolution: 0.1εr | |

| Free Water (Optional) | Range: 0-20% |

| Accuracy: 0.5% | |

| Resolution: 0.1% | |

| Other Parameters | |

| Permissible Flow Rate | 0.3…9L/min |

| Equivalent Inner Diameter | Φ8 mm (customizable) |

| Digital Output | RS485 MODBUS RTU, isolation voltage 2.5kV |

| Operating Power | DC9~30V, Max 5W |

| Permissible Oil Pressure | Max 1.0MPa |

| Applicable Fluids | Lubricating oils and hydraulic oils (synthetic and mineral-based), etc. |

| Fluid Temperature | -40 … 80 ℃ |

| Ambient Temperature | -40 … 85 ℃ |

| Storage Temperature | -50 … 120 ℃ |

| Housing Material | Stainless Steel, Anodized Aluminum, Polycarbonate |

| Dimensions | 150 × 80 × 80 mm (L × W × H) |

| Oil Port Interface | G1/4” (customizable) |

| Weight | < 4 kg |

| Protection Rating | IP66 |

| Connection Cable | Standard: 2-meter 5-core cable, M12*1.5 straight connector, or optional M12 waterproof gland |

| Electromagnetic Compatibility | EN61000, EN61326-1, EN61326-2, EN61326-4 |

| Explosion-Proof Rating (Optional) | Ex ib IIC T6 Gb |

Customers also viewed: