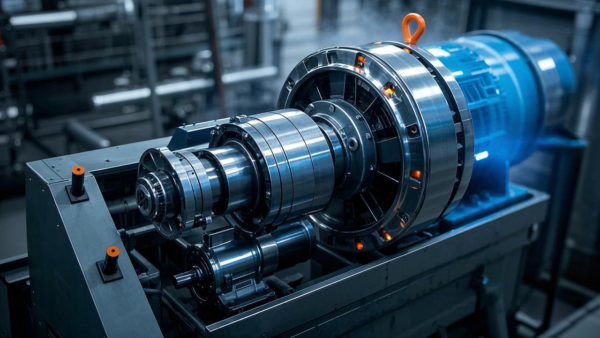

While there isn’t a specific international standard solely dedicated to the use of https://kongter.com/products/mps-1000-metal-particle-sensor/, several standards and guidelines encompass the broader context of condition monitoring, particle detection, and contamination control, which can be applied to metal particle sensors. These standards ensure the accuracy, consistency, and reliability of particle detection in various fluids and systems.

Relevant International Standards:

- ISO 4406:2017 – Hydraulic Fluid Power: Fluids: Method for Coding the Level of Contamination by Solid Particles:

– Provides a method for coding the level of contamination in hydraulic fluids based on the number of particles present. This standard is widely used for condition monitoring and can be applied to systems using metal particle sensors.

- ISO 11500:2020 – Hydraulic Fluid Power: Determination of the Particulate Contamination Level of a Hydraulic Fluid Power System:

– Specifies methods for determining the particulate contamination level of a hydraulic fluid system, including procedures for sampling and analyzing the fluid for contaminants.

- ISO 21018-3:2008 – Hydraulic Fluid Power: Monitoring the Level of Particles in the Fluid: Part 3: Use of Particle Counter with the Light Extinction Technique:

– This part of ISO 21018 specifies the use of particle counters using light extinction techniques to monitor particle levels in hydraulic fluids. While it focuses on hydraulic systems, the principles can be applied to metal particle sensors in other applications.

- ISO 16232-3:2007 – Road Vehicles: Cleanliness of Components and Systems: Part 3: Method of Extraction of Contaminants by Pressure-Rinsing:

– Relevant for the automotive industry, focusing on the cleanliness of components and systems. It provides methods for extracting and analyzing contaminants, including metal particles.

- ASTM D7596 – Standard Test Method for Automatic Particle Counting and Particle Shape Classification of Oils Using a Direct Imaging Integrated Tester:

– This standard outlines methods for using automatic particle counters to classify particles in oils by size and shape. It is particularly useful for condition monitoring and contamination analysis.

- ISO 13323-1:2000 – Particle Size Analysis – Image Analysis Methods – Part 1: Static Image Analysis Methods:

– Provides guidelines for analyzing particle size using image analysis methods. This can be relevant for metal particle sensors that use visual or imaging techniques to detect and classify particles.

Best Practices and Guidelines:

– Sampling and Testing Procedures:

– Follow standardized procedures for sampling fluids to ensure consistent and accurate results. Proper sampling techniques are crucial to avoid contamination and to get representative samples.

– Calibration and Maintenance:

– Regular calibration and maintenance of metal particle sensors are necessary to maintain their accuracy and reliability. Adhere to manufacturer guidelines and relevant standards for calibration intervals and procedures.

– Data Interpretation:

– Use standardized codes and methods, such as those provided in ISO 4406, to interpret data from metal particle sensors. This ensures consistent reporting and comparison of contamination levels.

– Documentation and Reporting:

– Maintain detailed records of testing, including methods used, calibration data, and results. This documentation is essential for traceability, compliance with standards, and effective maintenance planning.

Industry-Specific Guidelines:

– Aerospace:

– Comply with industry-specific standards and regulations for aircraft maintenance and monitoring, such as those from the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA).

– Automotive:

– Follow automotive industry standards for fluid cleanliness and contamination monitoring, which may include ISO and SAE (Society of Automotive Engineers) standards.

– Power Generation:

– Adhere to standards and guidelines from organizations such as the International Electrotechnical Commission (IEC) for monitoring and maintaining power generation equipment.

Conclusion:

While there may not be a single standard dedicated solely to metal particle sensors, various international standards and guidelines related to particle detection, condition monitoring, and contamination control can be applied. By adhering to these standards and best practices, industries can ensure the effective use of metal particle sensors for monitoring and maintaining the health of their equipment, leading to improved reliability, safety, and operational efficiency.