Description

Function

Monitor of AC & DC voltage

- MCM will display voltage between busbars and ground including negative busbar to ground and positive to ground. It also measures voltage for AC signal interruption.

- When system voltage is higher or lower than setting threshold in DC system malfunction, or when AC voltage exceeds setting value, warning info will be sent out with LED indicator and buzzer.

- Warning info can be sent to automation system via YX switching value and RS485 connector.

Insulation Monitor

- MCM will in real time monitor and display grounding resistance between busbars (positive and negative) and ground.

- When system voltage of positive-ground and negative-ground is unbalanced, and unbalanced value exceeds setting value, there will be warning info.

Grounding Detection

- The MCM will receive monitored data from DAMs in real time and analyze the grounding status of each branch circuit. It could accurately calculate grounding resistance and precisely judge which branch has ground fault, if any. During this process, it smartly bypasses the interferences from charger pulse, fluctuation of electrical level and so on.

- Grounding resistance will display on LCD screen and could be transfer to integrated automation system via RS485.

Current diagnosis

- There is current sensor on each DAM, and the measured current values are transferred to the MCM. This will help technicians know comprehensive status of the DC system and quickly eliminate malfunction timely.

Early warning for insulation problems

- The MCM has high accurate measurement up to 500K. It will monitor the long time trending for the grounding resistance between circuit and ground. This tendency of resistance changes will supply early warning before a ground fault happens. It will be very helpful for a preventative maintenance.

History record play back

- AC signal interference and grounding record will be automatically saved in This record will include time of AC interference & grounding, grounding resistance, interference voltage, grounding circuit and so on.

- It records up to 1000 events.

Voltage balance

- When ratio of voltage values (positive busbar to ground and negative busbar to ground) exceeds protection index of 1.222, this system will use compensation bridge to balance the voltage values of both busbar to ground. In another word, the ratio of positive-ground voltage and negative-ground voltage will become higher than 0.869. Or the ratio of negative-ground voltage and positive-ground voltage will be lower than 1.150.

Battery circuit monitor

- This monitoring system will monitor insulation/grounding status of battery circuit in real time with the help of data recorder and current clamps.

Measurement of distributed capacitance

- It can measure values distributed capacitance for the tested DC system.

Features

High performance hardware

- State-of-art designing with industrial chip and components.

- Overall processing capability is dynamically adjustable based on branch circuits (DAM). Maximally it supports dozens of CPU working at the same time.

- Each DC circuit uses independent high accurate 16-bit AD converter for data acquisition. Conversion speed is higher than 1000 times/second with resolutions higher than 1/50000

- DC current sensor resolution is as high as 0.1mA and accuracy is higher than 0.1%. It will automatically sense any small changes in the circuit.

Advanced data structure

- This system adopts unique DADC framework. This makes it flexible for onsite commission and system expansion. It is also powerful for data processing.

- DADC enables users to add different amount of DAMs. It is cost effective and smart for future update.

- DADC framework enables users to arrange position of DAMs as per onsite condition, convenient for wire connection and reduces signal interference.

- DADC balances MCM and DAMs for high accurate AD sampling and heavy load computation quantity. This ensures the effective operation of the complex SynSystem platform.

Smart software

- Digital signal enhancement technology:

- Processing method based on FIR digital signal processing will filer and amplify numerous AD sampling data, it will increase current sensor resolution of 0.1mA to 10 times.

- Technology of extraction of wavelet time frequency characteristic

- Different from traditional Fourier transform, wavelet analysis can extract signal characteristics in different time. It can accurately find out the instant and long time characteristics.

- Technology of characteristic model matching (CMM)

- It will integrate time frequency characteristics of all circuits, compute with system presetting characteristics and finally make smart judgment which is similar to analyzing procedure of human brains.

User friendly interface

- User friendly interface with easy going instruction on screen.

High security

- It uses DC current sensor for detection of current leakage without injecting any external signal. It has no interference to the tested circuit.

- All sampling units are independently installed. Defective units will not affect the normal option of DC system.

High reliability

- Anti-interference designing using both software and hardware ensures the stable operation for long time even in strong interference environment.

- Current sensor is auto calibrated periodically after the first calibration. This ensures it is accuracy.

- Current sensor supports hot plug, auto identification and self check in case of defection.

- DAMs support hot plug and auto identification. MCM will periodically correct clock of DAMs.

- SynBus between MCM and DAMs is self checked and it will display communication status in real time.

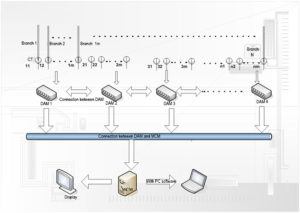

System Architecture

There are 2 ways of connection between MCM and DAM:

- Each DAM can connect directly with MCM via SynBus.

- Each DAM can connect with another DAM nearby via their HUB connectors and then to MCM. Communication between each DAM is decided by their unique IP code instead of physical position. This makes it flexible for installation onsite.

Both MCM and DAM are with hot plugging. MCM can automatically identify DAM without manual setting.

Each DAM can connect with up to 8 CTs. When CT is connected with DAM, DAM will automatically identify each CT without manual setting.

System Composition

The whole system is composed of 3 essential components: the Main Control Machine (MCM), Data Acquisition Module (DAM) and DC Current Sensor (CT).

| Name: | Control Machine (MCM) |

| Function: | It is the control unit of the whole system. It is also the interface for data display and parameter setting. |

| Connection: | MCM is fixed on power supply panel. |

| Power supply: | 85-300V from AC mains or DC |

| Dimension: | 48.4*20.2*12.9cm |

| Weight: | 2402g |

| Name: | Data Acquisition Module (DAM) |

| Function: | Monitor current status for the circuits that are connected. |

| Connection: | DAM unit is connected between MCM and CT with flexible installation location. |

| Power supply: | 12V,powered by MCM |

| Dimension: | 17*11.2*2.5 cm |

| Weight: | 253g |

| Name: | DC Current Sensor (CT) |

| Function: | Monitor current status for each circuit. |

| Connection: | CT is connected at outlet circuit of each DC power supply. |

| Option: | 10mA, 20mA & 100mA |

| Resolution: | 0.1mA |

| Accuracy: | 0.10% |

Technical Specification

- Monitor of grounding resistance:

Grounding resistance range: 0 - 50KΩ

Insulation decreasing range: 51-500KΩ

- Voltage range:

Positive to ground: 0 - 300V

Negative to ground: 0 - 300V

System total voltage: 0 - 300V

AC interference voltage: 0 - 300V

- Monitor of distributed capacitance: 0-999uF

- Anti-interference of DC distributed capacitance: >10000uF

- Suitable for DC system voltage: 24V, 48V, 110V, 220V or other customized voltage leveling.

- Monitor branch circuits: Up to 500

- Grounding resistance when MCM connected to DC system: >1000 K

- Accuracy of voltage monitoring:5%

- Grounding insulation warning: With YX output contact

- System low voltage warning: 198V (with YX output contact)

- System high voltage warning: 242V (with YX output contact)

- Connectors: Standard RS232/RS485/RS422 connectors, compatible with connectors of automation system.

- Environment temperature: -30℃ ~ +50℃。

- Relative humility: ≤96%

- Tolerance of DC voltage ripple: 2%

- Standard: CE marking, LVD standard

- Current range: customized as 10mA, 20mA & 100mA

- Current accuracy: 0.1

Customers also viewed: