Description

- Multilingual: English, Spanish, Germany, French and more to come

- Two units in one, smart switch to test internal resistance and conductance of battery.

- Including rugged test clamp and 2-section pin probe for different battery conditions

- Wide test range up to 6000Ah for Lead-Acid or Nickel-Cadmium single battery up to 16V

- Field proven accurate and repeatable measurement to identify battery health.

- Very fast and consistent test of battery or multiple batteries simply in several seconds

- It adopts advanced measurement way of AC signal discharge to test internal resistance

- User friendly TFT touch screen and keypad as alternative operation

- Universal micro-USB for firmware update, data export and battery charging

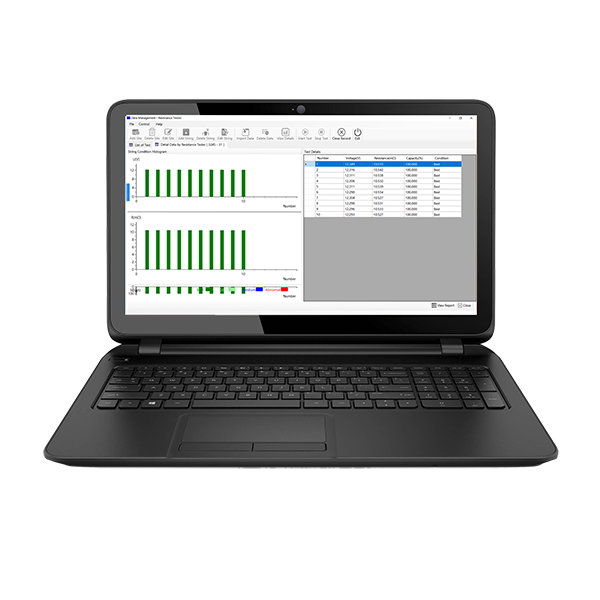

- Functional management software on PC for recording, analyzing measurement data and easy report printing out.

- Battery pack is durable in the field with testing time of 8-12 hours

- Up to 100,000 cells stored internally, unlimited with USB drive exportation

| Applications: | Test single Lead-Acid or Nickel-Cadmium cell or battery string (one by one after setting once). |

| Cell types supported: 1.2V, 2V, 6V, 12V and other customized types up to 6000Ah. | |

| Resistance range | Internal Resistance: |

| 0.001 mΩ–100mΩ | |

| Conductance: | |

| 100 – 19,990 Siemens | |

| Voltage range | 0.000V ~25V |

| Test Data Storage: | 100,000 cells stored internally, unlimited with USB drive exportation |

| Minimum test resolution – resistance -Voltage | |

| 0.001mΩ | |

| 1mV | |

| Test accuracy -conductance -voltage | |

| Resistance/Conductance: 2% | |

| Voltage: 0.5% | |

| User Programmable Functions: | • Customized battery types |

| • Low voltage alarm setting | |

| • High resistance alarm setting | |

| • Test mode (push button/touch screen/auto start) | |

| Cable Options: | • 2-section Pin probe |

| • Alligator Test Clamp | |

| • Custom cables by quotation | |

| Power supply | Li-ion battery (4000mAh), 8~12hours working time after full charge |

| Data Transfer: | USB via micro-USB cable |

| Storage Temperature: | -20~50℃ |

| Operation environment | 0℃ to 40℃, 90% R.H |

| Over Voltage Protection: | • Auto-reset disconnect |

| • Reverse polarity protected | |

| Measuring cells per string | 1≤cells≤254 |

| LCD display | 272*480 pixel, 4.3” TFT Touch Screen LCD |

| Housing Material: | Acid resistant ABS plastic santoprene overmold |

| Tester Dimensions: | L186*W98*H40 mm |

| Weight: | Main body: 0.45KG |

| Package: 3Kg | |

| Standard: | CE Marking, EMC standard |

The BT-301 Battery Condition Analyzer is widely applied in industries of:

- Telecom & communication power

- Uninterrupted Power Supplies (UPS)

- Utility transmission and distribution systems

- Data center, healthcare, education or financial

- Forklift and traction battery maintenance

- Refinery, mining and offshore platform

- Battery manufacture and inspection

Q: What is the difference among impedance, internal resistance and conductance testing?

A: Impedance testers and internal resistance testers are using different method of measurement. Impedance testing is generally injecting a current signal to battery so as to measure its resistance. This is proved to be unstable and inconsistent measurement when UPS batteries are in live condition.

Internal resistance test is generally using DC or AC signal discharge to measurement internal resistance and voltage of battery.

Conductance (unit: Simens) measurement is same as that of internal resistance (unit: Ohm). Their relationship is: S=1/R.

Kongter offers both options of measurement for internal resistance and conductance via discharging a low current AC signal. Customers with different measurement habits can find their right solutions accordingly.

BT-301 Battery Condition Analyzer can also switch between internal resistance testing and conductance testing.

Q: Do you use alligator testing clamp or pin probe for measurement of batteries?

A: Kongter offer both alligator testing clamp and pin probe for different types of batteries. User can select either as per their need.

Q: Can we test Internal Resistance/Conductance of multiple blocks of cell once?

A: No, we can not. Because our way of measurement is not the old way of signal injection. Also, measurement of battery internal resistance or battery conductance is to help users fast detect the consistency of whole battery string and figure out the weak batteries with high resistance (or low conductance). Measurement of multiple cells at the same time will make it difficult to judge which cells are weak.

Q: Can I use the battery tester to measure Ni-cd and Lithium batteries?

A: Yes, besides standard battery types of 2V, 6V and 12V lead acid batteries, there is customized setting in the battery tester menu where users can add uncommon battery types including Ni-cd and Lithium batteries.

Q: How should I connect the alligator testing clamp or pin probe with battery?

A: To obtain best measurement accuracy and consistency, we will suggest always connect the tester clamps or pin probes with battery posts.

Q: Is it idea device to test battery real capacity?

A: For accurate test of battery real capacity, we will suggest K-900 series DC load bank for battery string or BCD-3932T Battery Charger/Discharger unit for single cell.

Product Videos:

Customers also viewed: