Description

Unique Features

- Compliant with ASTM 8120 Standard

- 10-second rapid detection

- 0-2000ppm(mg/kg) wide test range

- Unaffected by aging, bubbles and moisture

- Only requires 5ml of sample

- <5ppm measurement repeatability

- Detection from nanometer to millimeter iron magnetic particles

- Compact and portable, no chemical consumables required

Specification

| Detection Content | Iron magnetic particle concentration in oil (μg/kg) | Display Interface | 4.3″ TFT Touch screen |

| Detection Range | 0~2000ppm | Data Storage | 2000 test records |

| Detection Lower Limit | 5ppm | Power Supply | DC24V, 0.25A |

| Repeatability | – 0~100ppm < 5ppm | Working humidity | 10~90%RH, non-condensing |

| – 100~500ppm < 2% or 5ppm (whichever is greater) | |||

| – 500~2000ppm < 1% | |||

| Resolution | 1ppm | Storage Temperature | -20~70℃ |

| Detection Time | <10s | Working Temperature | 10~45℃ |

| Sample Amount | 5mL | Applicable Fluid | Lubricating oil and hydraulic oil |

| Particle Response | From nanometer to millimeter (ESD effective diameter) | Dimensions | 20*19.2*14cm |

| Calibration Accessory | Three calibration samples included | Conforms to Standard | ASTM D8120 |

| IP Rating | IP34 | Weight | About 3kg |

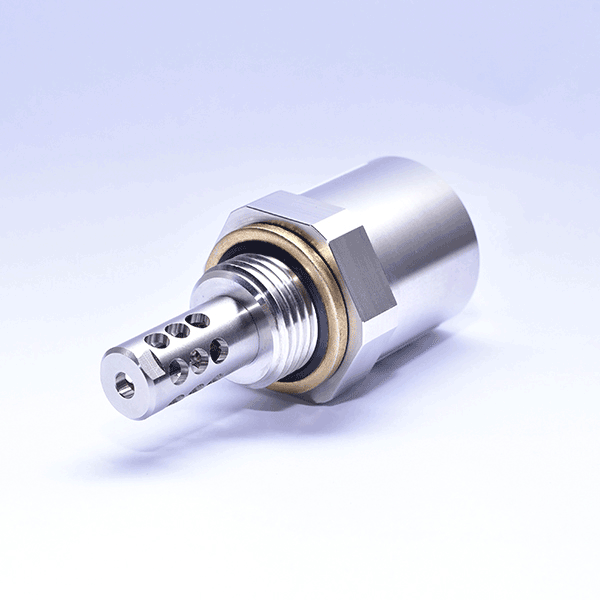

Measurement Principle

The core of the FCA-2000 consists of two precision-winding electromagnetic induction coils. One coil is used for real-time detection while the other serves as a reference comparison. When a 5ml sample tube is inserted into the instrument, iron magnetic particles such as iron, nickel, and cobalt cause changes in the magnetic field of the sensing coil, which is linearly related to the concentration of iron magnetic particles in lubricating oil.

Thus, it realizes the function of detecting the concentration of iron magnetic particles ranging from nanometers to microns in oil.

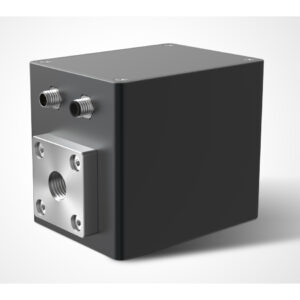

Customers also viewed: